CoreScan: Core Scanning & Geophysical Logging at High-tech Quality Level

With our core scanner system, you create a reliable system for structuring and evaluating your drill cores for construction, repository and exploration projects, save costs and manage data efficiently. Our scanner provides you with high-resolution images of your drill core in a unique 360 degree processing. The subsequent digital processing of the data ensures you the best and fastest results from your costly drillings. The CoreScan offers a resolution of up to 40px/mm and is suitable for cores with large diameters.

Digital Drill Core Library for Precise Analyses

Instead of laboriously evaluating information on paper, you structure and log the data from your core drillings digitally and efficiently in our CoreBase software. With the help of our Core Analysis software, you receive precise analyses and evaluations of your drill cores in 3D, which provide detailed information about rock strata and the storage conditions. All digital logs from the software can be accessed at any time from anywhere in the world, saving you the need to re-analyse already weathered drill cores.

Typical applications of the CoreScan system include complex projects in the field of deposit exploration or preservation of evidence for final repositories. In oil and gas exploration, our system offers the CoreScan UV as an additional tool for analyzing the distribution of mineral oil or fluorescent minerals such as scheelite. Further fields of application for the CoreScan system are geotechnical investigations for infrastructure projects such as rail and road routes or in construction planning as well as raw material deposits. You can identify fracture zones, classify rock types and mineral composition of the area or detect water-bearing zones. We offer our CoreScan system for sale with product training - or our interdisciplinary teams of experts can carry out the work for you on site.

Ideal for Both Round and Slabbed Drill Cores

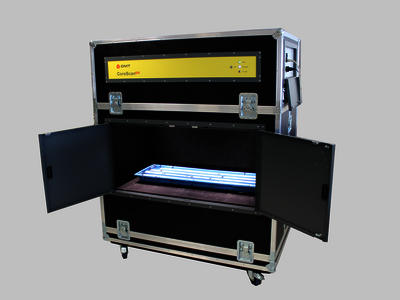

Another advantage of the CoreScan core imaging equipment is its portability. This means that there is no need for transporting the drill cores, but instead, they can be scanned and analysed on-site. It can also be combined with a televiewer for additional measurements. The scanning equipment can be operated in planar mode for slabbed cores, or in 360° and rotate the drill core sample to scan every side.

The digital drill core scanning and core imaging system provides:

- High-tech core logging

- Drill core imaging

- 360° core imaging

- Quantitative fracture analysis

- Digital core library and drill core management system

- Online data accessibility

- UV fluorescence imaging

DMT: Many years of expertise guarantee your project success

Acquisition, evaluation and storage of drill core images with high quality standards: Our experts have many years of experience in mining and in the exploration of deposits through geotechnical and scientific drilling. We offer you individual and cost-effective solutions for your projects. More security in planning provides a greater chance of successful completion of your project.

If you have any questions about the CoreScan system, we are happy to assist you. For more information on our systems and software, please click below:

ANCORELOG – Analytical Core Logger:

Sensor-based mineralogical-chemical and optical drill core analysis and digitalization

DMT´s latest development in core scanning technology is a modular multi-sensor device that combines analytical sensors and measures chemical and mineralogical drill core compositions in real-time. Additionally, smart machine learning techniques are used in order to classify the core samples into geological domains like e.g. lithologies or alteration zones. The perfect tool to support geologists and speed up decision-making!

CoreScan 3 – drill core scanning and logging device:

High-resolution images of your drill core in a unique 360 degree processing

The CoreScan 3 scanner provides high-resolution images of drill cores up to 1016 dpi, capturing both planar and 360° views. Integrated into CoreBase software, it facilitates documentation, archiving, and data presentation, which can be enhanced with geological findings. This technology is efficient for projects in exploration, geothermal energy, groundwater protection, and hazard prevention, saving significant time and resources.

Corescan UV – Professional images for the gas and oil industry:

An ultraviolet fluorescence imaging tool

A specialized ultraviolet fluorescence imaging tool primarily used for analyzing oil-bearing drill cores in oil and gas exploration. It can also detect fluorescing minerals like scheelite. The device captures high-quality images under UV and white light for cores up to 1.05 meters and core boxes of 1.15 x 0.64 meters. Its design minimizes scattered radiation and enhances image clarity. Images can be integrated into the CoreBase database for analysis. The CoreScan UV is portable, durable, user-friendly, and can operate in conjunction with the CoreScan 3, controlled by a single laptop.

CoreBase – A comprehensive software developed by DMT :

Managing and organizing scanned drill core data

This software facilitates the visualization, analysis, and documentation of drill cores, enhancing quality assurance and core preservation. It supports geological evaluations and structural analysis, allowing for the calibration and orientation of geological structures relative to geophysical logs. CoreBase includes CoreStructure for detailed structural analysis, offering functions for monitoring core composition and evaluating geomechanical parameters like RQD, FD, and FS. The system ensures quick online access to a digital drill core library, promoting efficient data exchange and minimizing data loss or mix-ups.

Client testimonials

"DMT CoreScan 3 Color, a portable core imaging device, acquired by LLP AktubNIGRI in August 2014, has proven to be excellent throughout the operation period and meets all specifications. The system allows to get a full image of the entire core circumference in 360° mode. High quality of images made in plane mode allows to see all structural and textural features of the sample. There are no complaints regarding results quality or the equipment."

B. K. Baimagambetov, General Director, AktubNIGRI, Kasachstan

"The perceived advantage to Crossrail is primarily the ability to review the strata in very high detail and in a relatively fresh and undisturbed condition at any time during the subsequent design and construction phases regardless of the time that has passed. Core that is stored long term, even that stored in optimum conditions, will show some sign of deterioration and in the worst cases may be completely useless to designers and contractors"

Mike Black, Geotechnical Manager, Cross London Rail Links Ltd (Crossrail)

"Since first introducing digital core scanning using the DMT Corescan to the UK geotechnical market we have found that many Clients, including those for major infrastructure projects such as Crossrail, Thames Tideway Tunnel and the High Speed Two (HS2) rail link, have specified the technique for use during ground investigations in recognition of the technical and commercial benefits that it brings."

Digby Harman, Innovation Manager, Soil Engineering Geoservices Ltd (Part of the Soletanche Bachy Group), UK

Sales & Distribution

Wolfram Gödde

Tel +49 201 172-2019

Fax: +49 201 172-1963

wolfram.goedde(at)dmt-group.LÖSCHEN.com

Product Manager

Carlos Garcia Piña

+49 201 172 1991

carlos.garciapina(at)dmt-group.LÖSCHEN.com