System solutions for tunnel ventilation

Competent, safe, cost-efficient: Our customized system solutions ensure clean breathing air in your tunnels, mines, sewage systems and landfills. We measure, monitor, plan and advise you on all safety-relevant questions concerning supply air, exhaust air and dust removal in your facilities. Our experts utilise the latest technologies and know-how in the fields of outgassing and metrological monitoring. In interdisciplinary teams they develop cost-reducing concepts to control gases, plan the air-conditioning and ventilation of your construction sites and guarantee the safety of your employees. In doing so, the schedule and smooth execution of your project or construction site operation is our top priority.

Benefit from the practice-oriented work of our internationally recognised experts, which balances operational safety and costs: we solve complex problems innovatively and efficiently. Many years of experience in the field of underground ventilation, a high standard of quality and the agile approach of our teams guarantee you maximum flexibility for the implementation of your projects. We rely on online tools and smart project management. For extensive projects and specific issues, we also draw on the international network of specialists and resources of the TÜV NORD GROUP. This means that even large-scale projects remain in one and the same hand.

Safe ventilation systems in tunnels

We work worldwide for operators of mines, tunnels and municipal sewage systems, users and manufacturers of tunnelling machines and monitoring equipment. Our system solutions optimize processes and increase operational safety for your project. We develop ventilation and monitoring concepts including the use of fans & measurement technology, determine gas inflows from the surrounding rock and calculate the required air flows. Our planning focuses on occupational health requirements and the safety of your employees.

Take advantage of our experience and knowledge.

Our services include investigations and expert opinions for central ventilation systems and other services in the following areas:

- Ventilation concepts for tunnel driving

- Monitoring concepts for air supply and detection of released pollutants

- Investigations into the release of gas from the rock body and its control

- Determination of the air requirement, taking into account the release of pollutants from diesel vehicles and harmful and flammable gases during tunnelling

- Determination of dust concentrations and dust control

- Design and dimensioning of special ventilation systems

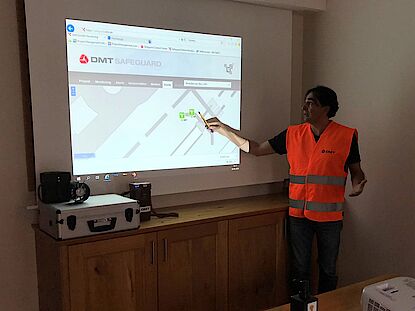

Our ventilation projects use SAFEGUARD software e.g. for central data storage for preservation of evidence. Developed in-house, the professional monitoring tool DMT SAFEGUARD enables you to permanently monitor demanding projects, analyze measurement data and receive automatic alarm notifications. Contact: safeguard(at)dmt-group.LÖSCHEN.com for information.

Railway infrastructure: ventilation of railway tunnels during track construction

We distinguish ourselves through our many years of experience in carrying out numerous projects on ventilation planning and hazardous substance measurements with precise analytical specifications and established measures in tunnels.

Our primary objective during maintenance work in tunnels is to protect the employees from hazardous substances in the tunnel atmosphere and the key to this is high-quality technical ventilation.

In summary, our services include the following:

- Planning and design of the ventilation system

- Creation of a ventilation, measurement and dust removal concept

- Operation of meteorological systems

- Appointment of ventilation officers

- Measurement of gaseous pollutants

- Analysis, evaluation and documentation of the measured values

- Preparation of project report

- Measurement of hazardous substances (A-, E- and quartz dust) by our accredited Laboratory for Air Hygiene

Ventilation systems for waste water networks

Benefit from our special expertise in the handling of all aspects relating to duct operation and the training of your operating personnel: Our teams develop ventilation concepts for safe operation of water ducts, support the execution of maintenance work and design solutions for the inspection of duct sections in a pollutant-free atmosphere.

Our services at a glance:

- Concepts for ventilation systems for all aspects of duct operation

- Calculations of the magnitude of the natural air exchange for normal and extra-long duct systems

- Studies on the necessity and expediency of technical ventilation systems

- Concepts for the metrological monitoring of the duct atmosphere

- Design, monitoring and control of the fresh air supply

- Design of fans and ventilation equipment

- Determination of the air requirement to avoid concrete corrosion

- Creation of explosion protection documents for gas endangered sewer systems

- Investigations to determine shaft distances for natural air exchange

- Evaluation of advantages and disadvantages of blowing or suction ventilation systems

Our qualification: Over 100 years of experience in mining

As a recognized independent expert body, high safety standards and an informative edge form the foundation of our services. DMT is involved in numerous patents and is active in research and development work. We cooperate closely with accredited institutes and approval bodies. Our experts are officially recognised. Our head office is located in Essen, Germany.