Smart Inspection & Monitoring - SIM

SIM is our innovative, digital overall concept for determining service lives and inspection intervals for plant components, consisting of fracture-mechanical damage tolerance analysis, engineering services, online monitoring and approval aspects:

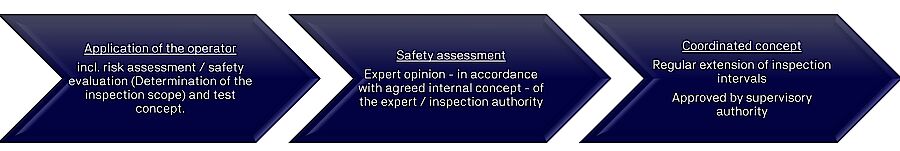

With our SIM concept, we offer you an efficient and reliable way to optimise the regular inspections of your plants. Thanks to the use of state-of-the-art technologies and our in-depth expertise, you can extend the intervals between inspections without compromising the safety and quality of your equipment. Our solution ensures that you remain compliant with applicable regulations and safety standards. We work closely with the relevant authorities and standards bodies to ensure that our inspection interval extension meets all legal requirements.

Advantages and economic benefits at a glance:

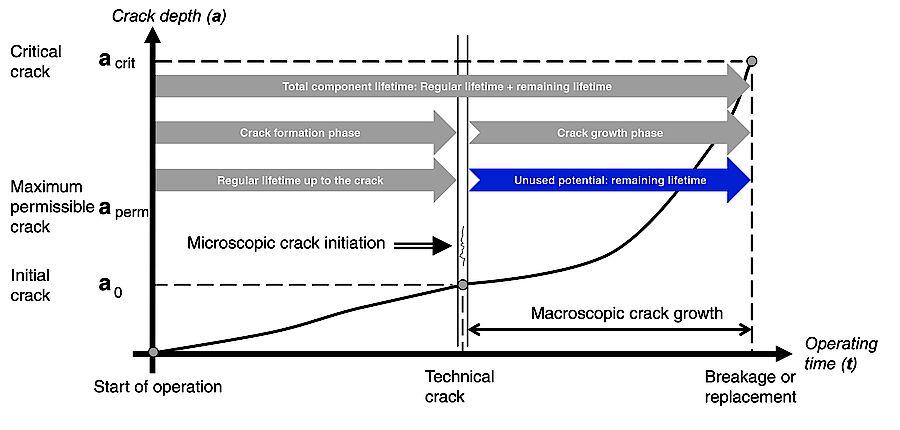

- Investment protection: With the help of SIM, tap into unused service life potential of your plant components (no premature component replacement).

- By optimising the inspection intervals, you can achieve considerable cost and time savings. Less frequent inspections mean fewer operational interruptions, lower maintenance costs and improved efficiency of your plants.

- Continuous use of SIM can also reduce the number of unplanned shutdowns and downtimes. SIM also helps to make maintenance costs more controllable.

- In addition, SIM represents a contribution to digitalisation and planning reliability in maintenance. Permissible inspection intervals can be calculated online and forecasts can be made depending on the system operation.

Lifetime evaluation of components

With "Smart Inspection & Monitoring", we offer you a solution with which the stability of your components against damage can be calculated more precisely. This means that the service life of the components can be significantly optimised in economic terms.

The concept is suitable for plant operators, inspectors and component manufacturers who deal with the challenges of components subject to alternating loads. The concept is also applicable to many energy sectors and industries with comparable process parameters:

- Solar thermal power plants

- Fuel cells

- Heat pumps/transmitters

- Adiabatic compressed air storage

- Thermal accumulators

- Plant components in the chemical & pharmaceutical industry

- Pressure equipment requiring monitoring (steam boilers, pressure vessels, pipelines)

- Work equipment subject to pressure and temperature (pumps, compressors, furnaces, cokers, pipelines, fittings, etc.)

The online monitoring of structural static, structural dynamic and vibro-acoustic data for damage prevention and maintenance serves as a basis.

Current regulations for SIM

As an important part of Smart Inspection & Monitoring, fracture mechanics damage tolerance analysis has already been incorporated into relevant regulations as a recognised measure for integrity assessment and test interval determination as well as a building block for condition monitoring, e.g. of thermally stressed boiler plants (including DIN EN 13445-3, VGB standard 506-00-2019-DE, VdTÜV bulletin MBDAMP 468 with recommendations for action for operators, inspection authorities and plant manufacturers).

Trust our SIM concept and optimise the monitoring of your industrial plants. Contact us today to learn more about our solution and develop a customised strategy for your requirements. Together, we will maximise the efficiency of your inspection processes and ensure the safe, smooth operation of your plants.