xHaleplus - the online system for determining the remaining lifetime of power plant and system components subject to alternating loads

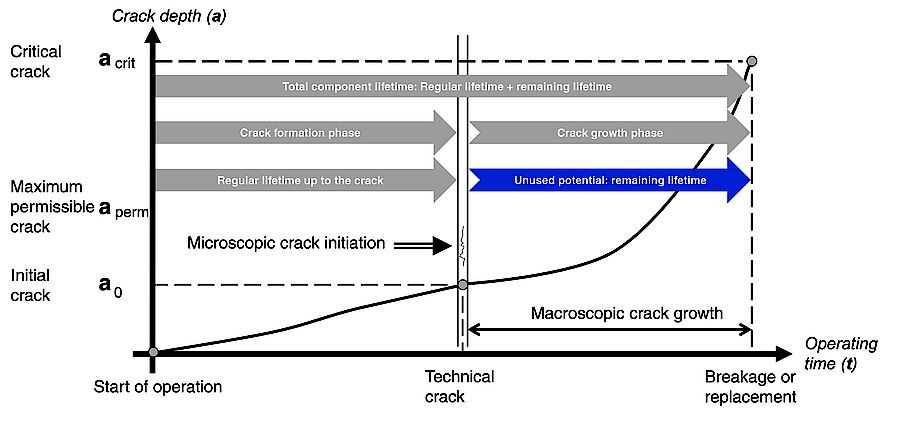

Power plant and plant components such as pipelines, valves and boilers are often subject to severe wear caused by alternating thermal loads. These loads can cause micro-cracks in the material, which develop into technical incipient cracks in the course of the operating time.

Normally, the use of the affected component then ends in an early repair measure or replacement, although the possible remaining lifetime has not yet been exhausted. Or relevant cracks are discovered too late. This results in unnecessary downtimes and repair costs.

This is where xHaleplus helps:

The online system provides time-accurate load data and calculates the growth of potential cracks step by step.

This can significantly optimize plant operation and save costs:

- xHaleplus offers functions to identify particularly damaging modes of operation of the equipment

- Cost savings through significantly better utilization of remaining service life

- Start-up optimization - increase of start-up speeds

- Determination of flexible, load-dependent inspection intervals

- Inspection intervals can be extended in accordance with the German Ordinance on Industrial Safety and Health* (see our SIM page)

- Avoidance of premature inspections and unnecessary component changes

- Economic analysis of yield and wear through simulation functions

- Our team of experts will assist you in implementing and using xHaleplus.

- We offer not only first-class technology, but also comprehensive consulting and support to ensure you realize the full potential of your equipment!

Please feel free to contact our specialists.

Contact us

- Michael Schneider

- products(at)dmt-group.LÖSCHEN.com

- Contact form