Mining Engineering Consulting: Safe & Comprehensive

More than 300 years of experience in providing Engineering & Consulting Services to and conducting research for the mining industry have shaped DMT into the strong and reliable mining engineering partner that we are today. From the first technical feasibility considerations and general issues of mine planning to closure and restoration, we provide economic and safe tailor-made solutions all around the globe. Among our many and varied successful international mining projects there are for example the realization of a gas laboratory (CH4) in Turkey, construction of a shaft landing in Germany or consulting on the avoidance of rock burst in Russia.

DMT's mining engineering consultants and our vast engineering services cover all issues of mining engineering, from mine design through operation to mine closure, including:

- Mine layout and extraction planning

- Strata control / rock mechanics: detailed planning of all mine workings

- Mine ventilation, gas management, gas drainage & mine gas utilisation

- Support design and bulk materials engineering

- Planning of infrastructure and logistics

- Mine water management, mine drainage

- Design of sedimentation basins and heaps

- Mine closure, abandoned mining & remediation

- Coke making technology

With DMT, you receive comprehensive mining engineering support, all from a single source.

Mining Engineering: Strata Control / Rock Mechanics to Determine Geotechnical Conditions

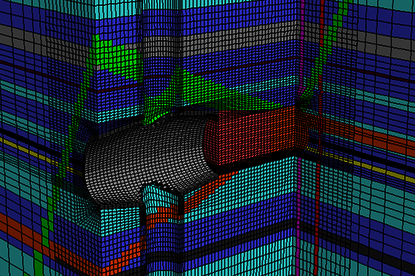

Strata control / rock mechanics can be a deciding factor in the success of any underground or open cast mining project, regardless of the type of raw mineral being exploited. In addition to the structure of the actual deposit, the geotechnical conditions often play a defining role in the selection of a suitable mining method and thus of the entire mine engineering planning. With the help of empirical, physical, and numerical models, we dimension all types of underground workings (shafts, landings, excavation areas, etc.), but also natural or artificial embankments etc. in opencast mines. As well as mine design work and geotechnical studies, we perform supplementary testing both in our laboratories and underground and provide construction supervision and development support in all mining fields.

Mine Ventilation & Gas Management: Prevention & Damage Control

Suitable ventilation of mines, tunnels, sewage systems or other underground workings is essential for safe working conditions. As well as maintaining the supply of respirable air for the workforce, DMT provides solutions for important ventilation issues such as the control of hazardous gases, vapours, or dusts, as well as heat and cold. In the field of gas control, we offer our clients complete systems to avoid any hazards, such as gas outburst. This includes the provision of a gas laboratory for measurement of gas content as well as fast and competent on-site consulting in the event of an accident, e.g. a gas explosion. Beside mining engineering, our services include:

- On site ventilation survey and gas measurement

- Software-based planning of ventilation networks

- Design of ventilation systems, gas drainage systems & reservoir modelling

- Planning of preventative measures against gas outbursts

- Provision of equipment for ventilation and degassing measures

- Integrated gas management concepts

- Training in mine ventilation and degassing

Mining Engineering for Mineral Extraction

The interaction of the individual components in extraction operations and mining engineering must be precisely coordinated in order to achieve a high level of productivity. Increasing exploitation performance and output are obviously central to this, as is the optimization of operation processes pursuant to the numerous mining related and economic conditions. We provide both comprehensive mine engineering planning and detailed engineering for extraction operations, all with one aim: enhancing the complex operations of your business. To achieve this DMT offers:

- Underground measurements e.g. cuttability

- Simulation of diverse extraction processes and machines

- Mechanical and process engineering for mine development operations

- Integrated concepts for new extraction operations

- Optimisation of existing mining operations

Construction & Backfill Materials Engineering

The hydraulic and pneumatic transport of construction and backfill materials requires specific process engineering know-how. In the context of designing such transportation processes, all sub-processes and boundary conditions must also be taken into account and closely coordinated. Our specialists in mining engineering, construction and backfill materials engineering work out the planning principles, support you in developing the composition of the mixture and also design and construct turnkey installations in cooperation with our partners.

Mineral Transport and Haulage

DMT has years of experience in designing haulage systems and carrying out cost-benefit analyses where appropriate to determine the necessary capacity of belt conveyors, trainsets, haulers and shaft haulage systems.

Our primary aim in mining engineering and consulting is always to ensure overall efficiency by keeping costs and operational downtimes to a minimum.

Mining Engineering for Mine Water Management

Our Hydrogeology and Ground Water Management department continues the work of the “Water Resources Management Office” founded in 1921 for the German hard coal mining industry. We support authorities and boards in fulfilling the specifications of the EU Framework Directive for Water (WFD).

We investigate the environmental impact of mine water drainage, facilities on the surface, tailings and waste dump sites on the amount and quality of groundwater and surface water. Our services are engaged from the planning stage of new projects right up to optimizing existing projects. But water management is also essential during and after mine closure. DMT offers proactive solutions in mining engineering and water management to address this problem responsibly and sustainably.

Reference

Processing Solutions for New & Existing Plants

Based on more than 100 years of processing experience, our mining engineering experts have extensive know-how of all kinds of raw materials. Whether processing trials to determine the basic data for process development, the detailed development of a process flow sheet or the subsequent Basic Engineering for the construction of new treatment facilities. We offer all manner of tailor-made processing solutions for new and existing operational plants, with safety.

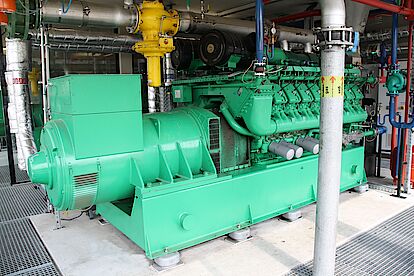

Mine Gas Utilization: Turnkey Systems & Customizable Mining Engineering Solutions

The methane in coal seam reservoirs is known by many names: firedamp, mine gas, coalbed methane (CBM), coal mine methane (CMM) or unconventional gas. In recent years it has also become known as a valuable natural resource for the generation of electricity and heat. One big advantage is that it can be captured in every phase of mining operations, be it before extraction of the actual coal reserve begins, during operation of the mine, after the mine has been abandoned or even exploited as a stand-alone resource from yet undisturbed seams. Not only does DMT engineer and deliver turnkey systems for the extraction, processing and utilisation of coalbed methane, we also customize our mining engineering solutions to meet the special requirements of the deposit and the mine gas quality.

Mine Closure and Remediation

DMT also assists you in the last stage of mining. Our mining engineers offer their expertise to ensure that your mining operation can be closed while leaving a minimal environmental footprint, preventing contamination and other long-term effects.

Furthermore, we provide solutions for dealing with Legacies of Abandoned Mines and Environmental Services & Rehabilitation

We are happy to advise you on these and any other mining engineering services.