Maximise the performance of your wind turbines with our innovative condition monitoring system WindSafe!

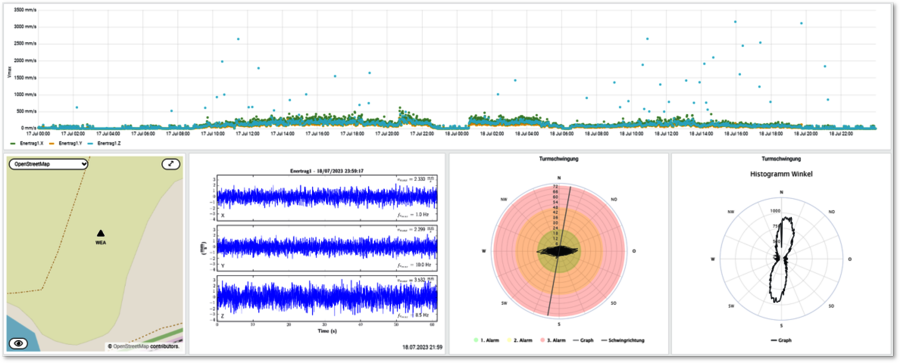

Our condition monitoring system WindSafe, based on DMT's powerful IoT platform SafeGuard, offers you a comprehensive solution for monitoring and optimising your turbines. Thanks to advanced sensor technology and intelligent data analyses, you can monitor the condition of your wind turbines in real time, detect potential problems at an early stage and minimise costly downtimes. Our systems detect impending damage up to 9 months in advance - enough time to take optimal action.

By continuously monitoring and analysing the performance data, you can identify inefficient operating states and, for example, power losses caused by misalignment This enables you to implement targeted optimisation measures and increase the yield of your wind turbines.

Rely on our condition monitoring system and maximise the performance and availability of your wind turbines. Contact us today for more information and to develop a customised solution for your requirements. Together we will ensure efficient and reliable use of renewable energy and contribute to the success of your wind turbines and farms.

Please feel free to contact our specialists.

Contact us

- Michael Schneider

- products(at)dmt-group.LÖSCHEN.com

- Contact form